ISSN :, ISBN :, PP : 0713 .

Analysis of energy saving opportunities in cement sector Cement manufacturing is the energy intensive process involves both thermal and electrical energy.

WhatsApp)

WhatsApp)

Analysis of energy saving opportunities in cement sector Cement manufacturing is the energy intensive process involves both thermal and electrical energy.

electricity consumption for grinding 1 mt of cement . Gulin provide the energy consumption in cement ball mill solution case for you.

Cement production are high pollution, high energy consumption industries,which does not meet modern industrial development of energy saving targets, in order to ...

Cement Clinker Grinding Plant Solutions We has the proper Cement Clinker Grinding Plant to meet your materials ... line grinding occupation demands electrical power ...

cement mill for cement plant grinding mill,US 10,000 50,000 / Set, New, Ball Mill, AC from Zhengzhou Yufeng Heavy Machinery Co., Ltd. on

Ernest Orlando Lawrence Berkeley National ... Specific fuel and electricity consumption per ton of cement ... to make finished cement, or clinkergrinding ...

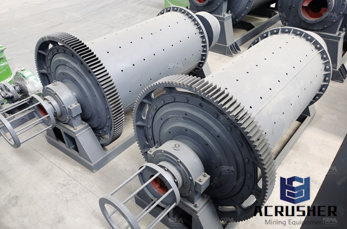

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

CEMENT INDUSTRY Output of a Seminar on Energy Conservation in Cement Industry Sponsored by United Nations Industrial Development Organization (UNIDO)

Verified Emission Reductions Monitoring Report . Energy efficiency project in the Ramla Cement Plant in Israel through instalment of new grinding technology

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Cement grinding system equipment investment is 120,000 Yuan per equipment in one hour, ... The electricity consumption of grinding system is about

Electricity Intensity Standards for the existing cement plants in the period of March 2010 – March 2012 in Iran. Type of the process. Consumption category

cement grinding electricity consumption nanomarkers. Electric consumption cement grinding You are here: Home Coal GrindingElectric consumption cement grindingLive ...

INDUSTRIAL CASE STUDY: THE CEMENT INDUSTRY CALMAC Study ID: Final Report Prepared for Pacific Gas and Electric Company San Francisco, California

Energy Efficiency and Saving in ... Large amounts of electricity are used grinding ... Grinding and milling account for % of cement/concrete energy consumption ...

electricity consumption for grinding of opc in vertical roller mill; ... The carbon footprint from electricity consumption for cement. Read more.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

cement grinding electricity consumption. Cement | Industrial Efficiency Technology Measures. Cement is a binding agent and is a key ingredient of the most used man ...

TABLE 8: ELECTRICITY CONSUMED BY CEMENT PLANTS, BY PLANT PROCESS 1 : Electricity consumed 2 : Average: GeneratedPurchased : Total 3: Cement: consumption

Electric Consumption Cement Grinding_sand ... cement grinding machine power consumption. cement grinding machine power ... Electricity Consumption For Grinding .

Grinding Aids Sika AG Sika Grinding aids are used to improve the production efficiency of cement grinding plants and their energy consumption.

Cement Grinding and Distribution ... Canadian Cement Industry 2008 Sustainability Report. 2008. ... analysis of only onsite electricity consumption was considered, ...

cement grinding electricity consumption, Cement dust collector QJD, the free encyclopedia. The recent history of the technology has been mainly concerned with ...

electricity consumption for raw grinding by 57 kWh ... savings of MBtu/ton blended cement. Electricity consumption...

WhatsApp)

WhatsApp)