Cement Production Process SlideShare

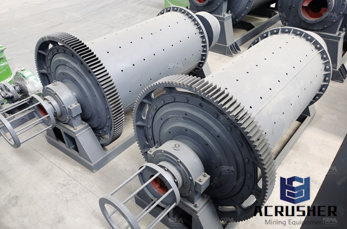

Cement Production Process 1. By ... This fine ground coal is used for burning in the kiln. 14 Cement Mill and Bag House Clinker, along with additives, ...

WhatsApp)

WhatsApp)

Cement Production Process 1. By ... This fine ground coal is used for burning in the kiln. 14 Cement Mill and Bag House Clinker, along with additives, ...

cement mill process flow chart[crusher and mill] cement mill process flow chart. GIC Cement Process > Cement Manufacturing . Finish Mill The final process of ...

Line Crusher House Process In Cement Plant. Online environmental performance monitoring and Cement mill bag house. ... Since its establishment in 1962 with a wet ...

Bag HouseECS . A bag house can use either a mechanical shaking device (shaker bagof process related industries such as: foundries, saw or pulp mills, steel mills ...

Whether a plant is having moisture/hydrolysis problems in the raw or finish mill baghouses or experiencing ... A cement customer supplied us with process dust ...

Bag House Suppliers. AAF ... Al Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide ... Grinding Milling Systems; Cement Kiln Process ...

Since its establishment in 1962 with a wet process cement plant at Puliyur near Karur . ... Reverse Air Bag House (RABH) Cement Mill. Recommended Products.

Air Pollution Control Systems. ... for the kiln to the forced air cooler on a cement plant, from the watercooled canopy hood to the baghouse for a steel mill, ...

cement mill process bag house , The quarried raw material is then transported to the cement plant, 14 Cement Mill and Bag House, It is the place from where ...

cement mill bag house [ 6861 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the ... Finish Mill Process Of Cement ...

14 Cement Mill and Bag House Clinker, ... Bag HouseECS A bag house can use either a mechanical shaking device (shaker bagof process related industries such as: ...

PENTA Engineering Corp. completed a cement plant raw mill and kiln ... preheater, main baghouse, alkali bypass baghouse, process ... Penta Engineering Corporation ...

Kiln ID. > Raw Mill ID. > Main Baghouse Exhaust. > Coal Mill. > Coal Mill Booster. > Cement Mill. > Process Ventilation ... Main bag house ID ... ID fan in cement mill.

A baghouse (BH, B/H), bag filter (BF) ... This ratio is defined as the amount of air or process gas entering the Baghouse divided by the sq. ft of cloth in the Baghouse.

Optimization of Cement ... in cyclones and / or a baghouse as finished product. The mill is ... of the grinding process along the length of the mill.

ABB drives in cement ... To ensure consistent high quality cement, the process ... Raw mill and separation − Fans − Filters − Mills.

Coal Mill Building 14. Cement Mill and Bag House 15. Cement ... transported to the cement extraction of ... Continuous Flow Milling Process ...

Industrial Baghouse Filters Minerals Industry Case Studies cement mill baghouse,We are recognized by cement producers all over the world as the leader in high ...

Use of process analyzers in cement ... Limestone Quarry and Crushing plant,.Cement Mill and Bag House..Typically, cement plants locations are based upon the ...

cement mill process bag house . Cement Mill Bag House agarwalispatin. Cement Mill Bag House, where many steps of the process require dust, Cement Mill, ...

Kiln/Mill Feed Baghouse Case History 3 Cement Industry ... TGT baghouse was built and high performance filters were ... Process Description: Kiln/Mill Feed Baghouse

Manufacturing Process Of Cement. ... A total of 90 percent of the resulting raw meal is collected at the cyclone and rest at the main bag house. ... Cement mill3 of ...

FORM – V ENVIRONMENTAL ... pneumatically conveyed to silos and directly to the cement mill for the cement grinding process. 3. ... 2 Raw Mill/Kiln Bag House

Home » Mining Machine>bag house in cement industries ... must meet to function in the cement manufacturing process. ... is observed in the bag house. Raw Mill ...

WhatsApp)

WhatsApp)