Blast Furnace Slag Material Description .

Blast Furnace Slag Material Description ORIGIN In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast ...

WhatsApp)

WhatsApp)

Blast Furnace Slag Material Description ORIGIN In the production of iron, iron ore, iron scrap, and fluxes (limestone and/or dolomite) are charged into a blast ...

Material Safety Data Sheet For . Ground Granulated Blast Furnace Slag . DURA SLAG™ Section I – Identity

The slaggranulation basin at Iscor. Slag granulator at a blast furnace at Iscor, Vanderbijlpark, South Africa. Bateman Launder Granulator at Impala Platinum''s plant,

Blast furnace slag is recovered by melting separation from blast furnaces that produce molten pig iron. It consists of nonferrous components contained in the iron ...

On Nov 7, 2013 Markus Kofler (and others) published: 316787 Dry Granulation of Blast Furnace Slag for Heat Recovery

Blast Furnance Slag User Guideline Embankment or Fill ... BLAST FURNACE SLAG User Guideline. Embankment or Fill. INTRODUCTION. ... ability to stabilize wet, soft ...

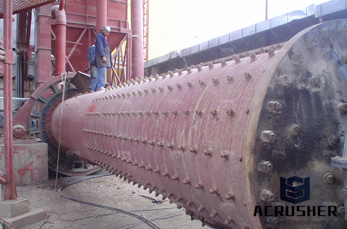

Blast furnace slag granulation at cast house. Blast Furnaces normally generate 250 to 350 Kg of liquid slag for every ton of hot metal produced.

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water ...

Blast furnace slag (BFS, ... is a nonmetallic byproduct of the manufacture of pig iron in a blast furnace. ... The wet process kilns operating in Europe are ...

Wet chemical analysis of silicon, calcium and magnesium in blast furnace slag: WANG Penghui: Wuhan Iron and Steel Group, Quality and Metrology Testing Center of ...

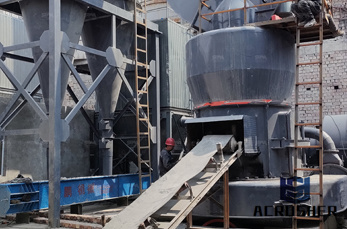

Wet Blast Furnace Slag Mill, Wholesale Various High Quality Wet Blast Furnace Slag Mill Products from Global Wet Blast Furnace Slag Mill Suppliers and Wet Blast ...

12/8/2015 Blast Furnace Slag, Essar Steel Algoma Inc. Page 1 of 7 Safety Data Sheet (SDS) Section 1: Identification 1 (a) Product Identifier: Blast Furnace Slag

Application and Research of Wetgunning Based on Colloidal silica for Main trough of Blast Furnace Chiong Chen* Sunward Refractories Co., Ltd.

After the sample of blast furnace slag was decomposed completely by hot dilute nitric acid and hydrofluoric acid,three portions of this test solution were ...

TABLE 1 Summary of recycled aggregates in construction TYPE OF AGGREGATE DESCRIPTION APPLICATIONS ... blast furnace slag into specially constructed slag .

A system for semiwet treating furnace slag, recovering waste heat and generating power comprises a furnace slag treatment system, a waste heat recovery system (300) and ...

Slag is the glasslike byproduct left over after a desired metal has been separated (, smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Wet and dry cured compressive strength of concrete containing ground granulated blastfurnace slag on ResearchGate, the professional network for scientists.

Read "Wet and dry cured compressive strength of concrete containing ground granulated blastfurnace slag, Building and Environment" on DeepDyve, the largest online ...

ii Crystallization of Blast Furnace Slags Pertaining to Heat Recovery Shaghayegh Esfani Doctorate Materials Science and Engineering University of Toronto

Blast Furnace Slag 45 As mentioned earlier, the reactivity of slag depends upon the glass content. The finer grains of granulated slag are rich in glass.

wet blast furnace slag. Material Safety Data Sheet – Lafarge in North America. Blast furnace slag granulation at cast house.

32 Shotcrete • Fall 2013 Susainailiy Sustainable Shotcrete Using BlastFurnace Slag By Philip Sawoszczuk, Dr. Michelle Nokken, and Dr. Marc Jolin

Slag handling is an important aspect of modern blast furnace operation. Today, blast furnace slag is a saleable product (granulated slag sand used as CO 2friendly ...

WhatsApp)

WhatsApp)